Stress and shear stress are fundamental concepts in the field of mechanics, particularly in the study of materials and their behavior under various types of loading. Understanding these concepts is crucial for engineers, researchers, and scientists who work with materials and structures, as it helps them design, analyze, and predict the performance of components and systems under different conditions.

When a material is subjected to external forces, it undergoes deformation, which can be either elastic or plastic, depending on the magnitude of the force and the properties of the material. The internal forces that arise within the material due to the external loading are known as stresses. Stress is a measure of the internal forces that are distributed over a small area of the material, and it is typically measured in units of force per unit area, such as pascals (Pa) or pounds per square inch (psi).

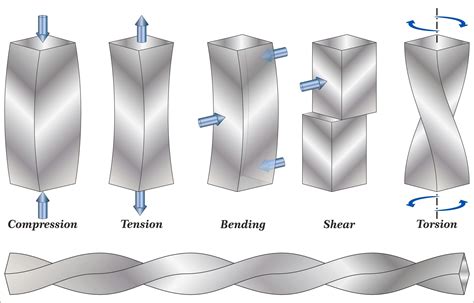

There are several types of stress, including tensile stress, compressive stress, and shear stress. Tensile stress occurs when a material is stretched or pulled apart, while compressive stress occurs when a material is compressed or squeezed. Shear stress, on the other hand, occurs when a material is subjected to a force that causes it to deform by sliding or rotating. Shear stress is a critical factor in many engineering applications, as it can lead to material failure, particularly in situations where the material is subjected to high levels of shear loading.

Understanding Shear Stress

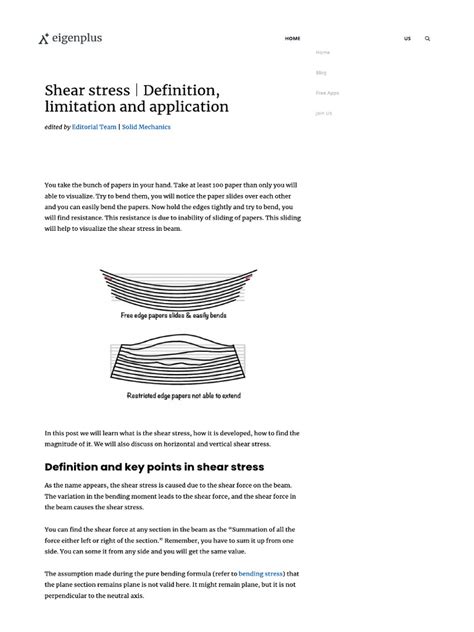

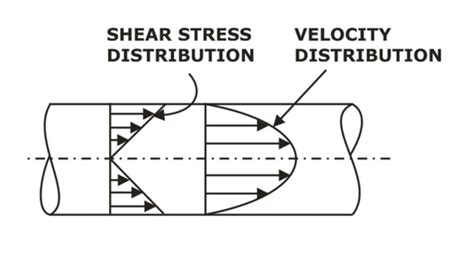

Shear stress is a type of stress that occurs when a material is subjected to a force that causes it to deform by sliding or rotating. It is a measure of the internal forces that are distributed over a small area of the material, and it is typically measured in units of force per unit area, such as pascals (Pa) or pounds per square inch (psi). Shear stress is a critical factor in many engineering applications, as it can lead to material failure, particularly in situations where the material is subjected to high levels of shear loading.

Shear stress can be calculated using the following formula:

τ = F/A

where τ is the shear stress, F is the force applied to the material, and A is the cross-sectional area of the material. The unit of shear stress is typically measured in pascals (Pa) or pounds per square inch (psi).

Types of Shear Stress

There are several types of shear stress, including pure shear, simple shear, and torsional shear. Pure shear occurs when a material is subjected to a force that causes it to deform by sliding or rotating, without any change in volume. Simple shear occurs when a material is subjected to a force that causes it to deform by sliding or rotating, with a change in volume. Torsional shear occurs when a material is subjected to a twisting force, which causes it to deform by rotating.

| Type of Shear Stress | Description |

|---|---|

| Pure Shear | Deformation by sliding or rotating without change in volume |

| Simple Shear | Deformation by sliding or rotating with change in volume |

| Torsional Shear | Deformation by rotating due to twisting force |

Key Points

- Stress and shear stress are fundamental concepts in mechanics, particularly in the study of materials and their behavior under various types of loading.

- Shear stress occurs when a material is subjected to a force that causes it to deform by sliding or rotating.

- There are several types of shear stress, including pure shear, simple shear, and torsional shear.

- Shear stress can be calculated using the formula τ = F/A, where τ is the shear stress, F is the force applied to the material, and A is the cross-sectional area of the material.

- Understanding shear stress is essential for designing and analyzing components and systems that can withstand various types of loading.

Applications of Shear Stress

Shear stress has numerous applications in various fields of engineering, including mechanical engineering, civil engineering, and materials science. In mechanical engineering, shear stress is used to design and analyze components such as gears, bearings, and shafts. In civil engineering, shear stress is used to design and analyze structures such as bridges, buildings, and foundations. In materials science, shear stress is used to study the behavior of materials under different types of loading, including tension, compression, and shear.

Shear stress is also used in various industries, including aerospace, automotive, and biomedical engineering. In aerospace engineering, shear stress is used to design and analyze components such as aircraft wings and fuselages. In automotive engineering, shear stress is used to design and analyze components such as engine blocks and gearboxes. In biomedical engineering, shear stress is used to study the behavior of biomaterials and to design medical devices such as implants and prosthetics.

Real-World Examples of Shear Stress

Shear stress is a common phenomenon that occurs in many real-world situations. For example, when a car is driven on a curve, the tires experience shear stress due to the friction between the tire and the road. When a person walks on a slippery surface, their feet experience shear stress due to the friction between the foot and the surface. When a material is cut or drilled, it experiences shear stress due to the force applied to the material.

| Example | Description |

|---|---|

| Tire on a curve | Shear stress due to friction between tire and road |

| Foot on a slippery surface | Shear stress due to friction between foot and surface |

| Material being cut or drilled | Shear stress due to force applied to material |

What is shear stress, and how is it different from other types of stress?

+Shear stress is a type of stress that occurs when a material is subjected to a force that causes it to deform by sliding or rotating. It is different from other types of stress, such as tensile stress and compressive stress, in that it involves a force that is applied parallel to the surface of the material, rather than perpendicular to it.

How is shear stress calculated, and what are the units of measurement?

+Shear stress is calculated using the formula τ = F/A, where τ is the shear stress, F is the force applied to the material, and A is the cross-sectional area of the material. The units of measurement for shear stress are typically pascals (Pa) or pounds per square inch (psi).

What are some common applications of shear stress in engineering and industry?

+Shear stress has numerous applications in various fields of engineering, including mechanical engineering, civil engineering, and materials science. It is used to design and analyze components such as gears, bearings, and shafts, as well as structures such as bridges, buildings, and foundations.