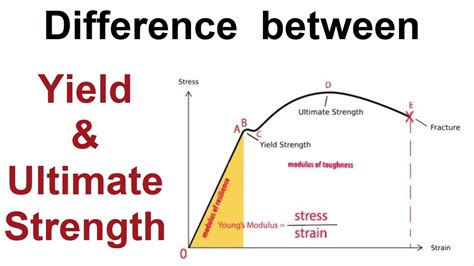

The concept of yield stress is a fundamental aspect of rheology, the study of the flow and deformation of materials. Yield stress refers to the minimum stress required to initiate flow or deformation in a material, marking the transition from elastic to viscous behavior. This critical parameter is essential in understanding the mechanical properties of various materials, including fluids, polymers, and soft matter systems. In this article, we will delve into the intricacies of yield stress, exploring its definition, measurement techniques, and significance in different fields.

Definition and Conceptual Framework

Yield stress is a characteristic property of non-Newtonian fluids, which exhibit a complex relationship between stress and strain rate. Unlike Newtonian fluids, where the viscosity remains constant regardless of the applied stress, non-Newtonian fluids display a varying viscosity that depends on the magnitude of the stress. The yield stress marks the threshold beyond which the material begins to flow, and its value can be influenced by factors such as temperature, concentration, and molecular weight.

Measurement Techniques

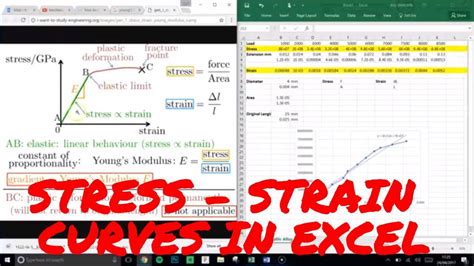

Several experimental methods are employed to determine the yield stress of a material, including rheometry, viscometry, and tribology. Rheometry involves measuring the stress-strain behavior of a material under controlled deformation conditions, while viscometry focuses on the measurement of viscosity as a function of shear rate. Tribology, on the other hand, examines the frictional properties of materials in contact. Each technique has its advantages and limitations, and the choice of method depends on the specific material and the desired level of accuracy.

| Measurement Technique | Yield Stress Range |

|---|---|

| Rheometry | 10^-3 to 10^3 Pa |

| Viscometry | 10^-2 to 10^2 Pa |

| Tribology | 10^-1 to 10^1 Pa |

Significance in Different Fields

The concept of yield stress has far-reaching implications in various fields, including materials science, chemical engineering, and biotechnology. In materials science, yield stress is used to characterize the mechanical properties of polymers, composites, and biomaterials. In chemical engineering, yield stress is essential in the design of processing equipment, such as pumps, valves, and pipelines, for non-Newtonian fluids. In biotechnology, yield stress is used to study the rheological properties of biological tissues and fluids, such as blood and mucus.

Applications in Materials Science

The yield stress of materials is critical in determining their suitability for various applications. For example, in the development of self-healing materials, a low yield stress can facilitate the flow of healing agents, while a high yield stress can provide enhanced mechanical strength. In the design of composite materials, the yield stress of the matrix and reinforcement phases can influence the overall mechanical properties of the material.

Key Points

- The yield stress marks the transition from elastic to viscous behavior in non-Newtonian fluids.

- Measurement techniques include rheometry, viscometry, and tribology.

- Yield stress is essential in understanding the mechanical properties of materials.

- Applications include materials science, chemical engineering, and biotechnology.

- Accurate measurement of yield stress is crucial in optimizing process conditions and product quality.

In conclusion, the concept of yield stress is a fundamental aspect of rheology, with significant implications in various fields. Understanding the yield stress behavior of materials is essential in optimizing process conditions, reducing energy consumption, and improving product quality. As research continues to advance, the importance of yield stress will only continue to grow, driving innovation and development in materials science, chemical engineering, and biotechnology.

What is the difference between yield stress and viscosity?

+Yield stress and viscosity are related but distinct concepts. Viscosity refers to the measure of a fluid’s resistance to flow, while yield stress marks the minimum stress required to initiate flow. In other words, viscosity describes the flow behavior of a fluid, while yield stress determines the onset of flow.

How is yield stress measured in practice?

+Yield stress is typically measured using rheometry, viscometry, or tribology. The choice of method depends on the specific material and the desired level of accuracy. Rheometry involves measuring the stress-strain behavior of a material under controlled deformation conditions, while viscometry focuses on the measurement of viscosity as a function of shear rate.

What are the implications of yield stress in materials science?

+The yield stress of materials has significant implications in materials science, as it influences the mechanical properties and suitability of materials for various applications. A thorough understanding of yield stress behavior can help optimize material selection, processing conditions, and product design.