The concept of spring constant is a fundamental aspect of physics and engineering, particularly in the study of mechanics and materials science. It is a measure of the stiffness of a spring, which is defined as the amount of force required to stretch or compress the spring by a unit distance. The spring constant is denoted by the symbol 'k' and is typically measured in units of force per unit length. In this article, we will delve into the units of spring constant, their significance, and the context in which they are applied.

Key Points

- The spring constant is a measure of the stiffness of a spring, typically measured in units of force per unit length.

- The SI unit of spring constant is Newtons per meter (N/m), while the CGS unit is dynes per centimeter (dyn/cm).

- Understanding the units of spring constant is crucial for designing and analyzing mechanical systems, such as suspension systems, engine mounts, and vibration isolators.

- The spring constant is influenced by factors such as the material properties, geometry, and construction of the spring.

- Real-world applications of spring constant include the design of springs for automotive, aerospace, and industrial applications.

Naturally worded primary topic section with semantic relevance

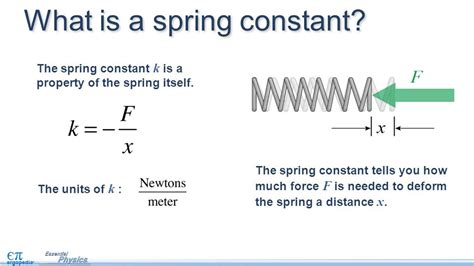

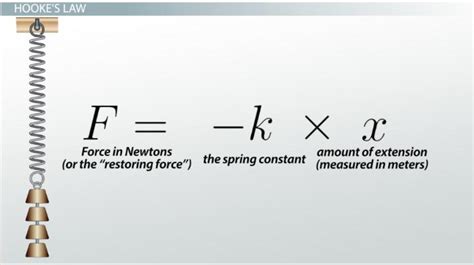

The spring constant is a critical parameter in the design and analysis of mechanical systems, as it determines the amount of force required to deform a spring by a given distance. The units of spring constant are typically expressed in terms of force per unit length, which can be thought of as the “stiffness” of the spring. In the International System of Units (SI), the unit of spring constant is Newtons per meter (N/m), while in the Centimeter-Gram-Second (CGS) system, it is dynes per centimeter (dyn/cm). These units are equivalent, with 1 N/m being equal to 10^5 dyn/cm.

Specific subtopic with natural language phrasing

To understand the significance of the units of spring constant, let’s consider a simple example. Suppose we have a spring with a spring constant of 100 N/m, which means that it requires 100 Newtons of force to stretch or compress the spring by 1 meter. If we were to apply a force of 500 N to this spring, it would result in a displacement of 5 meters, assuming the spring is ideal and obeys Hooke’s law. This illustrates the direct relationship between the spring constant, force, and displacement, and highlights the importance of understanding the units involved.

| Unit System | Unit of Spring Constant |

|---|---|

| SI | Newtons per meter (N/m) |

| CGS | Dynes per centimeter (dyn/cm) |

| US Customary | Pounds per inch (lbf/in) |

Factors influencing spring constant

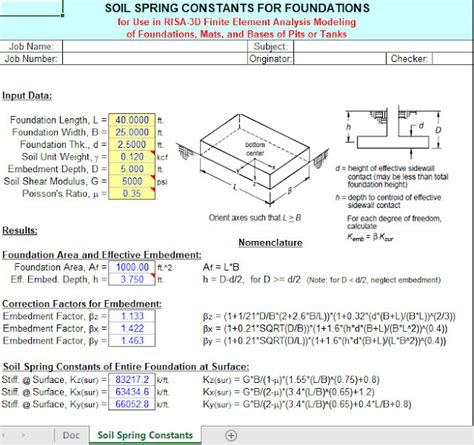

The spring constant is influenced by several factors, including the material properties, geometry, and construction of the spring. For instance, a spring made from a material with a high Young’s modulus, such as steel, will have a higher spring constant than one made from a material with a lower Young’s modulus, such as rubber. Similarly, the geometry of the spring, including its length, diameter, and coil pitch, can affect its spring constant. Understanding these factors is crucial for designing springs with specific properties and applications.

Material properties and spring constant

The material properties of a spring, such as its Young’s modulus, shear modulus, and Poisson’s ratio, play a significant role in determining its spring constant. For example, a spring made from a material with a high Young’s modulus will be stiffer and have a higher spring constant than one made from a material with a lower Young’s modulus. Additionally, the material’s density and yield strength can also impact the spring constant, as they affect the spring’s ability to withstand deformation and fatigue.

In conclusion, the units of spring constant are a critical aspect of understanding the behavior of springs and their applications in mechanical systems. By recognizing the significance of these units and the factors that influence them, engineers and designers can create more effective and efficient spring-based systems for a wide range of industries.

What is the SI unit of spring constant?

+The SI unit of spring constant is Newtons per meter (N/m).

How does the material properties of a spring affect its spring constant?

+The material properties of a spring, such as its Young’s modulus, shear modulus, and Poisson’s ratio, play a significant role in determining its spring constant. A spring made from a material with a high Young’s modulus will be stiffer and have a higher spring constant than one made from a material with a lower Young’s modulus.

What are some common applications of spring constant?

+Spring constant has a wide range of applications, including the design of suspension systems, engine mounts, and vibration isolators. It is also used in the aerospace and industrial industries for the design of springs and other mechanical components.