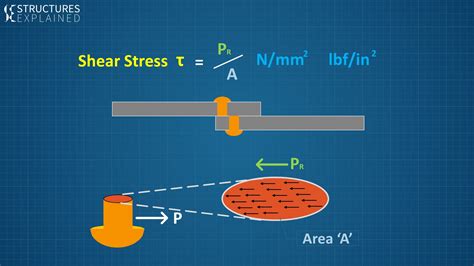

Sheer stress, a fundamental concept in the realm of mechanics and materials science, refers to the internal forces that are distributed within a material, causing it to deform or change shape. This phenomenon is a critical aspect of understanding the behavior of various materials under different types of loading conditions. The concept of sheer stress is essential in the design and analysis of structures, machines, and mechanisms, as it plays a significant role in determining their strength, stability, and durability. In this article, we will delve into the world of sheer stress, exploring its definition, causes, effects, and applications, as well as discussing the various methods used to analyze and mitigate its impact.

Key Points

- Sheer stress is a type of internal force that causes a material to deform or change shape.

- The magnitude of sheer stress depends on the type of loading condition and the material's properties.

- Sheer stress can lead to material failure, such as cracking or fracture, if it exceeds the material's strength limits.

- Understanding sheer stress is crucial in the design and analysis of structures, machines, and mechanisms.

- Various methods, including experimental testing and numerical simulation, can be used to analyze and mitigate the effects of sheer stress.

Understanding Sheer Stress

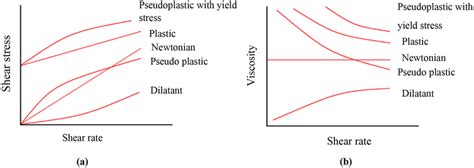

Sheer stress occurs when a material is subjected to a force that causes it to deform by sliding or rotating along a plane parallel to the direction of the force. This type of stress is typically characterized by a pair of equal and opposite forces that act on opposite faces of a small cube of material, causing it to deform by changing its shape. The magnitude of sheer stress depends on the type of loading condition, such as tension, compression, or torsion, and the material’s properties, including its Young’s modulus, Poisson’s ratio, and yield strength.

Causes and Effects of Sheer Stress

Sheer stress can be caused by various factors, including external loads, residual stresses, and thermal gradients. When a material is subjected to sheer stress, it can lead to a range of effects, including deformation, cracking, and fracture. The magnitude of sheer stress required to cause material failure depends on the material’s strength limits, which can be affected by factors such as temperature, humidity, and fatigue. Understanding the causes and effects of sheer stress is essential in designing and analyzing structures, machines, and mechanisms to ensure their safety and reliability.

| Material Property | Value |

|---|---|

| Young's Modulus (MPa) | 200,000 |

| Poisson's Ratio | 0.3 |

| Yield Strength (MPa) | 300 |

Methods for Analyzing and Mitigating Sheer Stress

Several methods can be used to analyze and mitigate the effects of sheer stress, including experimental testing, numerical simulation, and analytical modeling. Experimental testing involves subjecting a material or structure to a controlled loading condition and measuring its response, while numerical simulation uses computational models to predict the behavior of a material or structure under various loading conditions. Analytical modeling involves using mathematical equations to describe the behavior of a material or structure and predict its response to different loading conditions.

Experimental Testing

Experimental testing is a crucial step in understanding the behavior of materials and structures under sheer stress. Various testing methods, including tensile testing, compressive testing, and torsion testing, can be used to measure the mechanical properties of a material and its response to different loading conditions. The results of experimental testing can be used to validate numerical simulations and analytical models, ensuring that they accurately predict the behavior of materials and structures under sheer stress.

What is the difference between sheer stress and normal stress?

+Sheer stress and normal stress are two types of internal forces that act on a material. Sheer stress causes a material to deform by sliding or rotating along a plane parallel to the direction of the force, while normal stress causes a material to deform by stretching or compressing in the direction of the force.

How can sheer stress be mitigated in structures and machines?

+Sheer stress can be mitigated in structures and machines by using design techniques such as reinforcement, bracing, and optimization. These techniques can help to reduce the magnitude of sheer stress and minimize the risk of material failure.

What are the implications of sheer stress in materials science and engineering?

+The implications of sheer stress in materials science and engineering are significant, as it can affect the safety, reliability, and efficiency of structures, machines, and mechanisms. Understanding sheer stress is essential in designing and analyzing these systems to ensure their performance and minimize the risk of material failure.

In conclusion, sheer stress is a fundamental concept in the realm of mechanics and materials science, and its understanding is crucial in designing and analyzing structures, machines, and mechanisms. By exploring the definition, causes, effects, and applications of sheer stress, as well as the various methods used to analyze and mitigate its impact, we can develop more efficient and reliable designs that minimize the risk of material failure. As a materials scientist, it’s essential to consider the effects of sheer stress when designing and analyzing structures, machines, and mechanisms, and to use the latest techniques and technologies to mitigate its impact and ensure the safety and reliability of these systems.