The Material Safety Data Sheet (MSDS) is a critical document that provides detailed information about the safe handling, use, storage, and disposal of chemical products. It is a vital resource for workers, employers, and emergency responders who may be exposed to hazardous substances. The MSDS is typically prepared by the manufacturer or supplier of the chemical product and is designed to provide a comprehensive overview of the product's hazards, risks, and safety precautions.

Historically, the concept of MSDS dates back to the 1970s, when the U.S. Occupational Safety and Health Administration (OSHA) introduced the Hazard Communication Standard (HCS) to ensure that workers have access to information about the chemicals they work with. Over the years, the MSDS has evolved to become a standardized document that is widely recognized and used globally. Today, the MSDS is an essential component of workplace safety and health programs, and its importance cannot be overstated.

Key Points

- The MSDS provides critical information about chemical hazards, risks, and safety precautions.

- It is a vital resource for workers, employers, and emergency responders who may be exposed to hazardous substances.

- The MSDS is typically prepared by the manufacturer or supplier of the chemical product.

- It is a standardized document that is widely recognized and used globally.

- The MSDS is an essential component of workplace safety and health programs.

MSDS Components and Requirements

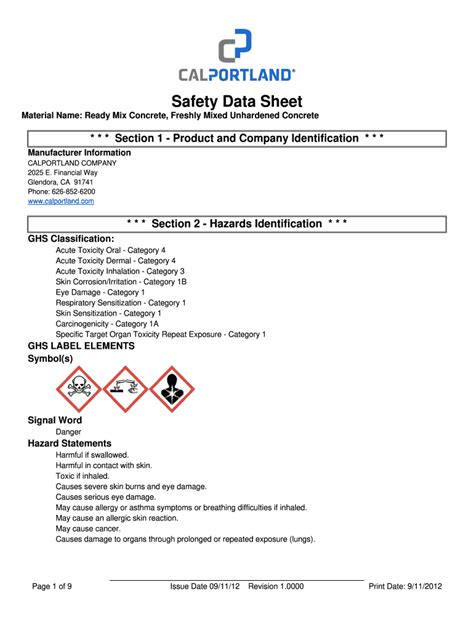

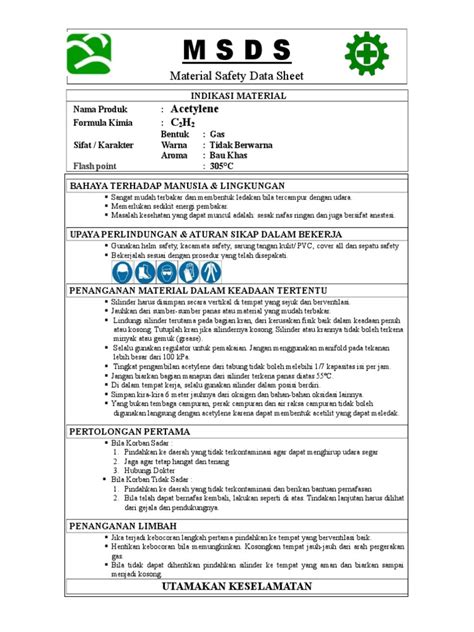

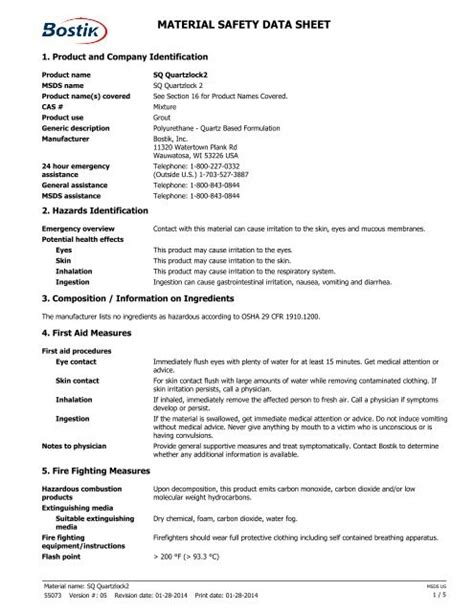

A typical MSDS contains 16 sections, which provide detailed information about the chemical product, including its identity, hazards, first aid measures, fire-fighting measures, and disposal considerations. The sections are:

- Section 1: Identification

- Section 2: Hazard(s) Identification

- Section 3: Composition/Information on Ingredients

- Section 4: First Aid Measures

- Section 5: Fire-Fighting Measures

- Section 6: Accidental Release Measures

- Section 7: Handling and Storage

- Section 8: Exposure Controls/Personal Protection

- Section 9: Physical and Chemical Properties

- Section 10: Stability and Reactivity

- Section 11: Toxicological Information

- Section 12: Ecological Information

- Section 13: Disposal Considerations

- Section 14: Transport Information

- Section 15: Regulatory Information

- Section 16: Other Information

Each section provides critical information that helps users understand the chemical product's hazards, risks, and safety precautions. The MSDS must be written in a clear and concise manner, using language that is easy to understand, and must be updated regularly to reflect new information or changes to the chemical product.

Importance of MSDS in Workplace Safety

The MSDS plays a crucial role in workplace safety and health programs. It provides workers with the information they need to handle chemical products safely, and helps employers to develop effective safety protocols and training programs. The MSDS also helps emergency responders to respond effectively in the event of a chemical spill or release.

According to the U.S. Occupational Safety and Health Administration (OSHA), the MSDS is an essential component of a workplace safety and health program. Employers must ensure that workers have access to MSDSs for all chemical products used in the workplace, and must provide training on how to read and understand the information contained in the MSDS.

| MSDS Section | Importance in Workplace Safety |

|---|---|

| Section 1: Identification | Provides critical information about the chemical product's identity and hazards. |

| Section 4: First Aid Measures | Provides information on how to respond in the event of exposure to the chemical product. |

| Section 8: Exposure Controls/Personal Protection | Provides information on how to prevent exposure to the chemical product and what personal protective equipment (PPE) to use. |

MSDS and Regulatory Compliance

The MSDS is subject to various regulatory requirements, including the U.S. Occupational Safety and Health Administration’s (OSHA) Hazard Communication Standard (HCS). The HCS requires employers to provide workers with access to MSDSs for all chemical products used in the workplace, and to provide training on how to read and understand the information contained in the MSDS.

In addition to OSHA's HCS, the MSDS is also subject to other regulatory requirements, including the U.S. Environmental Protection Agency's (EPA) Toxic Substances Control Act (TSCA) and the European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation.

Employers must ensure that their MSDSs comply with all relevant regulatory requirements, including the HCS, TSCA, and REACH. Failure to comply with these regulations can result in significant fines and penalties, as well as reputational damage and loss of business.

Best Practices for MSDS Management

Effective MSDS management is critical to ensuring workplace safety and regulatory compliance. Employers should develop a comprehensive MSDS management program that includes the following best practices:

- Ensure that all chemical products used in the workplace have an up-to-date MSDS.

- Provide workers with access to MSDSs for all chemical products used in the workplace.

- Provide training on how to read and understand the information contained in the MSDS.

- Ensure that MSDSs are easily accessible and readily available in the workplace.

- Regularly review and update MSDSs to reflect new information or changes to the chemical product.

What is the purpose of an MSDS?

+The purpose of an MSDS is to provide detailed information about the safe handling, use, storage, and disposal of chemical products.

What information is typically included in an MSDS?

+An MSDS typically includes information about the chemical product's identity, hazards, first aid measures, fire-fighting measures, and disposal considerations.

Who is responsible for preparing an MSDS?

+The manufacturer or supplier of the chemical product is typically responsible for preparing an MSDS.

In conclusion, the MSDS is a critical document that provides essential information about chemical hazards, risks, and safety precautions. It is a vital resource for workers, employers, and emergency responders, and plays a crucial role in workplace safety and health programs. Employers must ensure that their MSDSs comply with all relevant regulatory requirements, including the HCS, TSCA, and REACH, and must develop a comprehensive MSDS management program to ensure effective MSDS management.

Meta Description: Learn about the importance of Material Safety Data Sheets (MSDS) in workplace safety and regulatory compliance. Discover how to manage MSDSs effectively and ensure compliance with relevant regulations. (147 characters)