Ion exchange resins have been a crucial component in various industrial processes, including water treatment, chemical synthesis, and pharmaceutical manufacturing. These resins are designed to remove impurities from solutions by exchanging ions, hence their name. The efficiency and effectiveness of ion exchange resins depend on several factors, including the type of resin, the nature of the solution being treated, and the operating conditions. Here are five key tips for optimizing the use of ion exchange resins:

Key Points

- Choosing the right type of ion exchange resin for the specific application, considering factors such as the type of ions to be exchanged and the operating conditions.

- Ensuring proper regeneration and maintenance of the resin to maintain its ion exchange capacity and extend its lifespan.

- Optimizing the operating conditions, including flow rate, temperature, and pressure, to achieve the best possible ion exchange efficiency.

- Monitoring and controlling the quality of the influent and effluent streams to prevent fouling and ensure consistent performance.

- Considering the environmental and economic impacts of ion exchange resin use, including waste disposal and the potential for resin recycling or reuse.

Understanding Ion Exchange Resins

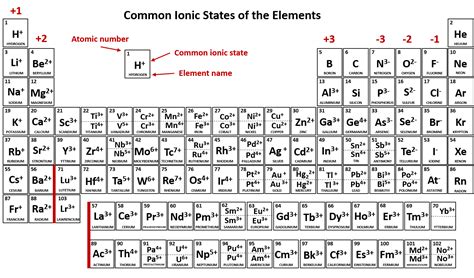

Ion exchange resins are versatile tools in industrial processes, offering a way to remove contaminants and achieve high purity levels in solutions. They work by exchanging ions with the solution they are in contact with, a process that can be tailored to specific applications by choosing resins with the appropriate functional groups. For instance, cation exchange resins can remove positively charged ions (cations) from a solution, while anion exchange resins target negatively charged ions (anions). The choice between these types depends on the nature of the contaminants and the desired outcome.

Selecting the Right Resin

The selection of the right ion exchange resin is critical for the effectiveness of the ion exchange process. This involves considering the type of ions to be removed, the concentration of the solution, and the operating conditions such as temperature and pH. For example, strong acid cation exchange resins are effective over a wide pH range and can remove alkaline earth metals, while weak acid cation exchange resins are more selective and may be preferred for removing heavy metals. Similarly, strong base anion exchange resins can remove a wide range of anions, including chloride, sulfate, and nitrate, but may require careful control of the pH to optimize their performance.

| Type of Resin | Application | Operating Conditions |

|---|---|---|

| Strong Acid Cation Exchange Resin | Water softening, heavy metal removal | Wide pH range, high temperature resistance |

| Weak Acid Cation Exchange Resin | Selective removal of heavy metals, recovery of valuable metals | Narrow pH range, lower temperature resistance |

| Strong Base Anion Exchange Resin | Removal of chloride, sulfate, and nitrate from water | High pH requirement, potential for organic fouling |

Operational Considerations

Beyond the selection of the appropriate resin, several operational factors can influence the efficiency and longevity of ion exchange systems. The flow rate, for instance, affects the contact time between the solution and the resin, with higher flow rates potentially reducing the effectiveness of the ion exchange reaction. Temperature and pressure are also critical, as they can influence the kinetics of the ion exchange reaction and the stability of the resin. Furthermore, the frequency and method of resin regeneration are vital for maintaining the resin’s ion exchange capacity over time.

Regeneration and Maintenance

Ion exchange resins have a limited capacity for ion exchange and must be regenerated periodically to restore their effectiveness. The regeneration process typically involves passing a solution through the resin that reverses the ion exchange reaction, restoring the resin to its original state. The choice of regenerant and the conditions under which regeneration is performed can significantly affect the efficiency of the process and the lifespan of the resin. Regular maintenance, including cleaning and inspection, is also essential to prevent fouling and ensure consistent performance.

What is the primary mechanism by which ion exchange resins remove contaminants from solutions?

+Ion exchange resins remove contaminants by exchanging ions with the solution they are in contact with, a process that can be tailored to specific applications by choosing resins with the appropriate functional groups.

How does the choice of ion exchange resin affect the ion exchange process?

+The choice of ion exchange resin affects the ion exchange process by determining the type of ions that can be removed, the efficiency of the removal, and the operating conditions required for optimal performance.

What are the key operational considerations for optimizing the performance of ion exchange systems?

+The key operational considerations include the flow rate, temperature, pressure, and the frequency and method of resin regeneration, as well as monitoring and controlling the quality of the influent and effluent streams.