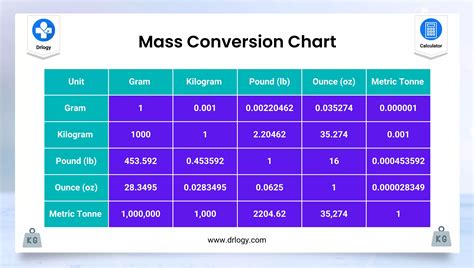

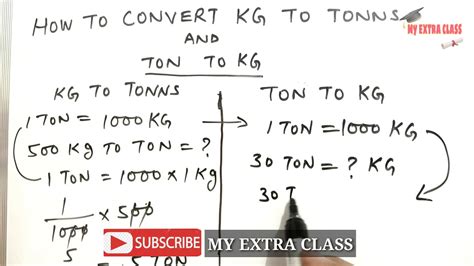

The concept of weight and its measurement is fundamental across various industries, including construction, manufacturing, and transportation. Understanding the significance of a 3-ton weight is crucial for professionals and individuals alike, as it pertains to the capacity, capability, and safety of equipment, vehicles, and structures. A 3-ton weight is equivalent to 6,000 pounds, a metric that is commonly referenced in the context of lifting, hauling, and supporting heavy loads. This guide aims to delve into the nuances of a 3-ton weight, exploring its applications, implications, and the considerations that come with handling such masses.

Key Points

- A 3-ton weight is equivalent to 6,000 pounds, a critical metric in industries involving heavy lifting and hauling.

- The applications of 3-ton weights include construction, manufacturing, and transportation, where precise load calculations are essential for safety and efficiency.

- Understanding the capabilities and limitations of equipment designed to handle 3-ton weights is vital for operational safety and compliance with regulatory standards.

- Load calculation and distribution are critical factors in managing 3-ton weights, requiring careful consideration of center of gravity, balance, and the structural integrity of the lifting or supporting apparatus.

- Regular maintenance and inspection of equipment are necessary to ensure the safe handling of 3-ton weights, preventing accidents and prolonging the lifespan of the machinery.

Applications and Implications of 3-Ton Weights

The relevance of a 3-ton weight is evident across multiple sectors, where the ability to lift, move, or support heavy loads is a defining factor in operational efficiency and safety. In construction, for instance, cranes and hoists are regularly employed to handle materials and equipment that may approach or exceed this weight threshold. Similarly, in manufacturing, the production and movement of heavy machinery or components often necessitate the use of forklifts, pulleys, and other lifting devices capable of managing 3-ton loads.

Construction and Building

In the construction industry, understanding and working with 3-ton weights is essential for several reasons. Firstly, the weight of construction materials, such as steel beams, concrete blocks, and prefabricated elements, must be accurately calculated to ensure that the lifting equipment used can safely handle the load. This includes considering not just the weight but also the size and shape of the materials to avoid accidents due to improper balancing or overloading. Moreover, the structural elements of buildings themselves, such as floors and roofs, are designed with specific weight capacities in mind, making it crucial to adhere to these limits to prevent structural failures.

| Material | Approximate Weight per Unit |

|---|---|

| Steel Beam | 100-500 pounds per linear foot |

| Concrete Block | 30-40 pounds per block |

| Prefabricated Wall Panel | 1,000-3,000 pounds per panel |

Transportation and Logistics

The transportation industry, including trucking and shipping, frequently deals with cargo that may weigh up to or exceed 3 tons. The capacity of vehicles, trailers, and shipping containers to safely carry such loads is a critical consideration. This involves not only ensuring that the vehicle or container can structurally handle the weight but also that the cargo is properly secured to prevent shifting during transit, which could lead to accidents or damage.

Load Calculation and Distribution

Load calculation and distribution are paramount when dealing with 3-ton weights. This involves understanding the center of gravity of the load, ensuring that it is balanced and secured properly to the lifting or carrying device. Improperly balanced loads can lead to dangerous situations, including the tipping of vehicles or the failure of lifting equipment. Therefore, professionals in these industries must be adept at calculating and managing weights to ensure safe and efficient operations.

Furthermore, regulatory compliance is another aspect that must be considered. Different jurisdictions have specific laws and guidelines regarding the maximum weights that can be transported on public roads or handled in certain environments. Being aware of and adhering to these regulations is essential for avoiding legal issues and ensuring public safety.

What is the primary consideration when handling a 3-ton weight in a construction setting?

+The primary consideration is ensuring that the lifting equipment is capable of safely handling the weight and that the load is properly balanced and secured to prevent accidents.

How does the transportation industry ensure the safe transport of 3-ton weights?

+The industry ensures safe transport through proper load calculation and distribution, securing the cargo, and adhering to regulatory weight limits for vehicles and roads.

What are the implications of exceeding the 3-ton weight limit in manufacturing and production environments?

+Exceeding the weight limit can lead to equipment failure, accidents, and regulatory non-compliance, highlighting the need for precise weight calculations and adherence to safety protocols.

In conclusion, managing and working with 3-ton weights requires a deep understanding of the technical, safety, and regulatory aspects involved. Whether in construction, manufacturing, or transportation, the ability to accurately calculate, safely handle, and efficiently move heavy loads is fundamental to operational success and public safety. As industries evolve and the demand for heavier lifting capacities increases, the importance of expertise in this area will only continue to grow, underscoring the need for ongoing education, training, and adherence to best practices in weight management.