The 5 to 8 inches guide is a critical measurement range in various industries, including construction, manufacturing, and design. Understanding the significance of this range and how it applies to different contexts is essential for professionals and individuals working with specific dimensions. In this article, we will delve into the importance of the 5 to 8 inches guide, exploring its applications, implications, and the factors that make it a crucial consideration in numerous fields.

Introduction to the 5 to 8 Inches Guide

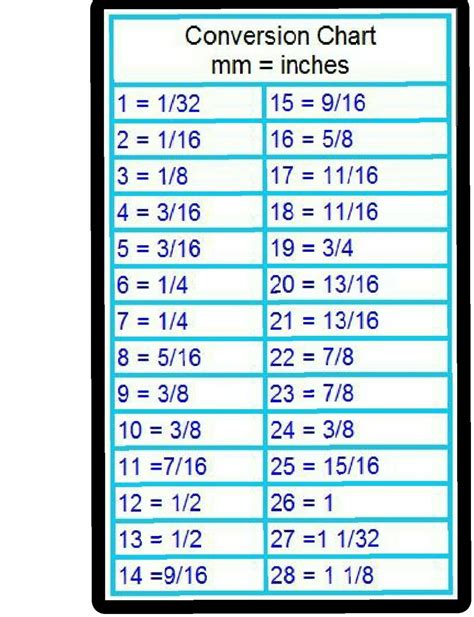

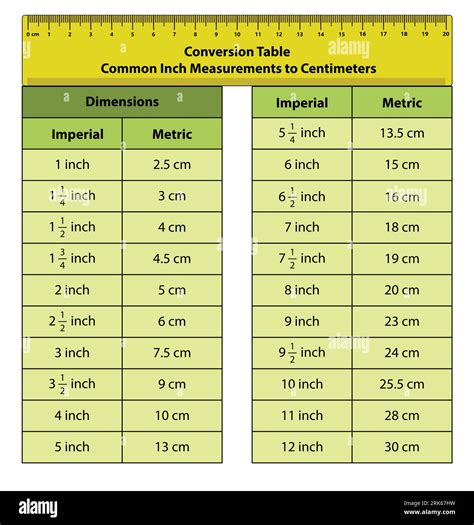

The 5 to 8 inches guide refers to a specific range of measurements that have become a standard in various industries. This range is not arbitrary but is based on a combination of factors, including human ergonomics, material properties, and functional requirements. For instance, in construction, the 5 to 8 inches range often relates to the width of lumber, the spacing of studs, or the depth of certain architectural features. In manufacturing, it might pertain to the size of components, the clearance between parts, or the dimensions of packaging. Understanding why this range is preferred involves looking into the historical development of these standards, the practical applications, and the regulatory frameworks that support them.

Historical Context and Development

The origins of the 5 to 8 inches guide can be traced back to early building practices and the evolution of standardized measurements. The use of the inch as a unit of measurement, derived from the British Imperial system, has been influential. Over time, as construction and manufacturing techniques advanced, the need for standardized dimensions became apparent to ensure compatibility, efficiency, and safety. The 5 to 8 inches range emerged as a compromise between different requirements, balancing factors such as strength, cost, and usability. For example, in woodworking, a 6-inch wide board is often considered a standard size because it provides a good balance between stability and manageability.

| Application Area | Typical Dimensions |

|---|---|

| Construction Lumber | 5 to 8 inches (width) |

| Manufacturing Components | 5 to 8 inches (length or width) |

| Architectural Features | 5 to 8 inches (depth or width) |

Applications and Implications

The applications of the 5 to 8 inches guide are diverse, ranging from the construction of buildings and bridges to the manufacture of furniture and consumer goods. In each case, adhering to this range can ensure that the final product meets certain standards of quality, safety, and performance. For example, in construction, using lumber within this width range can help in achieving the desired structural integrity while also considering factors like thermal insulation and acoustic performance. In manufacturing, components within this size range might be easier to handle, assemble, and maintain, contributing to overall efficiency and cost-effectiveness.

Technical Specifications and Considerations

When working with the 5 to 8 inches guide, professionals must consider a variety of technical specifications and constraints. These include material properties (such as strength, durability, and weight), functional requirements (like load-bearing capacity or resistance to environmental factors), and regulatory compliance (adhering to building codes, safety standards, and environmental regulations). For instance, the choice between using a 5-inch or an 8-inch wide beam in construction might depend on the expected load, the span length, and the type of material used. Similarly, in manufacturing, the decision to use components within this size range could be influenced by factors like production costs, market demand, and competitive differentiation.

Key Points

- The 5 to 8 inches guide is a standardized measurement range used across various industries.

- It balances human ergonomics, material properties, and functional requirements.

- Historical development and practical applications have solidified its importance.

- Technical specifications, regulatory compliance, and environmental considerations are crucial.

- Adhering to this range can ensure quality, safety, and performance in final products.

In conclusion, the 5 to 8 inches guide is a fundamental principle in several industries, reflecting a deep understanding of the interplay between design, functionality, and practicality. By recognizing the significance of this measurement range and its underlying factors, professionals can create products and structures that are not only efficient and safe but also meet the evolving needs of users and the environment.

What are the primary factors influencing the 5 to 8 inches guide?

+The primary factors include human ergonomics, material properties, and functional requirements, which collectively contribute to the standardization and widespread adoption of this measurement range.

How does the 5 to 8 inches guide impact construction practices?

+In construction, adhering to the 5 to 8 inches guide can influence the choice of lumber, the spacing of structural elements, and the overall design of buildings, ensuring they meet specific standards of safety, durability, and performance.

What role does regulatory compliance play in the application of the 5 to 8 inches guide?

+Regulatory compliance is crucial as it ensures that products and structures not only meet the 5 to 8 inches guide but also adhere to broader safety standards, environmental regulations, and building codes, thereby protecting public health and safety.

Meta Description: Discover the significance of the 5 to 8 inches guide across industries, from construction to manufacturing, and how it impacts design, functionality, and safety standards.