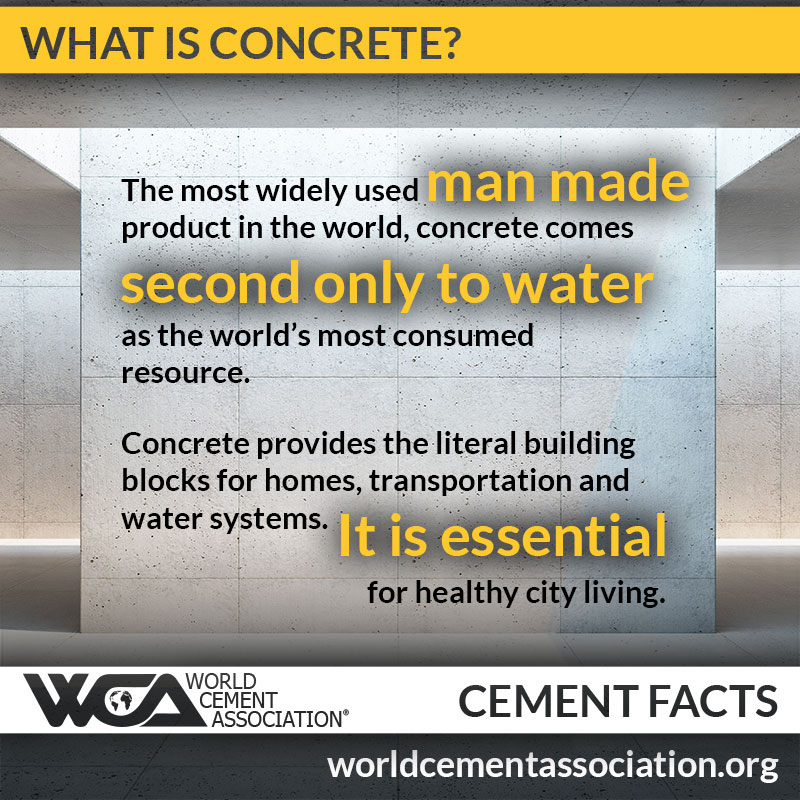

Cement is a fundamental component in the construction industry, serving as a binding agent in concrete, mortar, and other materials. Its importance cannot be overstated, given the critical role it plays in building infrastructure, residential housing, and commercial developments. The following discussion aims to delve into five key facts about cement, exploring its history, production process, environmental impact, types, and applications.

Key Points

- The history of cement dates back to ancient civilizations, with evidence of its use found in Egyptian and Roman structures.

- Cement production involves a complex process that includes mining, grinding, and heating limestone and other materials to high temperatures.

- The environmental impact of cement production is significant, with the industry being a major contributor to greenhouse gas emissions.

- There are several types of cement, each with its unique properties and applications, including Portland cement, blended cement, and specialty cement.

- Cement is used in a wide range of applications, from construction and infrastructure development to decorative and architectural features.

History of Cement

Cement has a rich and fascinating history that spans thousands of years. The earliest evidence of cement use dates back to ancient civilizations in Egypt, Greece, and Rome. The Romans, in particular, were known for their advanced engineering skills and use of a sophisticated form of cement, known as Opus caementicium, to build structures such as the Pantheon and the Colosseum. This early form of cement was made by mixing lime with volcanic ash and water, creating a durable and long-lasting binding agent.

Production Process

The production of cement involves a complex and energy-intensive process. The primary components of cement include limestone, clay, sand, and other minerals, which are mined from quarries and open-pit mines. These raw materials are then crushed, ground, and mixed together in a specific proportion to create a homogeneous blend. The mixture is then heated to high temperatures, typically between 1400°C and 1450°C, in a rotary kiln, where it undergoes a series of chemical reactions that transform the raw materials into cement clinker. The clinker is then cooled, ground into a fine powder, and mixed with other additives to produce the final product.

| Type of Cement | Description |

|---|---|

| Portland Cement | The most common type of cement, known for its high strength and durability. |

| Blended Cement | A combination of Portland cement and other materials, such as fly ash or slag, to improve workability and reduce costs. |

| Specialty Cement | A range of specialized cements, including white cement, colored cement, and expansive cement, designed for specific applications and decorative effects. |

Environmental Impact

The production of cement has a significant environmental impact, primarily due to the large amounts of energy required to heat the raw materials to high temperatures. The cement industry is estimated to be responsible for around 8% of global greenhouse gas emissions, making it one of the largest contributors to climate change. Additionally, the extraction of raw materials, such as limestone and clay, can result in habitat destruction and water pollution. However, there are ongoing efforts to reduce the environmental impact of cement production, including the use of alternative fuels, waste reduction, and the development of more sustainable types of cement.

Applications of Cement

Cement is used in a wide range of applications, from construction and infrastructure development to decorative and architectural features. It is a fundamental component in concrete, which is used to build roads, bridges, buildings, and other structures. Cement is also used in mortar, which is used to bond bricks, blocks, and other masonry materials together. Additionally, cement is used in a variety of decorative applications, such as plastering, rendering, and flooring. Its versatility, durability, and strength make it an essential material in the construction industry.

What is the difference between cement and concrete?

+Cement is a binding agent, while concrete is a mixture of cement, water, and aggregate (such as sand, gravel, or crushed stone). Concrete is a composite material that uses cement as a binder to hold the aggregate particles together.

How is cement produced?

+Cement production involves a complex process that includes mining, grinding, and heating limestone and other materials to high temperatures. The resulting clinker is then cooled, ground into a fine powder, and mixed with other additives to produce the final product.

What are the different types of cement?

+There are several types of cement, including Portland cement, blended cement, and specialty cement. Each type has its unique properties and applications, and is suited to specific construction requirements and environmental conditions.

In conclusion, cement is a vital component in the construction industry, with a rich history, complex production process, and significant environmental impact. Its versatility, durability, and strength make it an essential material in building infrastructure, residential housing, and commercial developments. As the demand for sustainable and resilient construction materials continues to grow, the development of more environmentally friendly types of cement and construction practices will play a critical role in shaping the future of the industry.