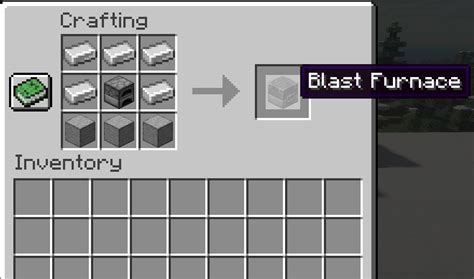

The blast furnace, a staple in many industrial and crafting systems, is a complex piece of equipment that requires a deep understanding of its operational parameters and recipe configurations. For those familiar with its workings, the blast furnace is an indispensable tool for smelting ores and producing metals with high efficiency. However, mastering its recipes and optimizing its use can be a daunting task, especially for newcomers. In this comprehensive guide, we will delve into the intricacies of the blast furnace, exploring its fundamental principles, essential recipes, and strategic considerations for maximizing its potential.

Key Points

- Understanding the basic principles of blast furnace operation, including temperature control and material input.

- Mastery of essential recipes for common metals and alloys, such as iron, copper, and bronze.

- Optimization strategies for fuel efficiency, output quality, and minimizing waste products.

- Advanced techniques for crafting complex alloys and high-value materials.

- Integration of the blast furnace into a larger production system, including supply chain management and inventory control.

Blast Furnace Basics: Operational Overview

At its core, a blast furnace is a type of metallurgical furnace that uses the combustion of fuel, typically in the form of coal or charcoal, and a blast of air to smelt ores and produce metals. The process involves several key steps: loading the furnace with ore and fuel, igniting the mixture, and controlling the airflow to achieve the optimal temperature for smelting. The blast furnace’s efficiency and output quality are heavily dependent on maintaining precise control over these parameters, making a deep understanding of its operational dynamics crucial for successful use.

Temperature Control and Fuel Efficiency

Temperature control is perhaps the most critical aspect of blast furnace operation. Different metals and alloys have specific smelting points, and achieving these temperatures without exceeding them is essential for producing high-quality output while minimizing waste. Fuel efficiency also plays a significant role, as excessive fuel consumption can not only increase operational costs but also lead to unnecessary environmental impacts. By optimizing fuel input and airflow, operators can achieve a balance between smelting efficiency and environmental sustainability.

| Material | Smelting Point | Fuel Requirement |

|---|---|---|

| Iron Ore | 1250°C | 3 units of coal |

| Copper Ore | 1085°C | 2 units of charcoal |

| Bronze (90% Copper, 10% Tin) | 950°C | 2.5 units of coal |

Essential Recipes and Advanced Techniques

Beyond the basics of operation, mastering a variety of recipes is essential for unlocking the full potential of the blast furnace. From common metals like iron and copper to more complex alloys such as bronze and steel, each material has its unique recipe that requires precise measurements of ore, fuel, and sometimes additional metals or minerals. Advanced techniques, such as fluxing and alloying, can further enhance the quality and diversity of the output, allowing for the creation of high-value materials that are indispensable in various applications.

Alloying and Fluxing Techniques

Alloying involves combining two or more metals to create a material with properties that are superior to those of its individual components. Fluxing, on the other hand, refers to the use of substances that reduce the melting point of the ore, making the smelting process more efficient. Both techniques require a deep understanding of metallurgy and the properties of different materials, as well as precise control over the blast furnace’s operational parameters. By mastering these techniques, operators can produce a wide range of alloys and materials with unique properties, catering to diverse industrial and crafting needs.

What is the ideal fuel for smelting iron ore in a blast furnace?

+The ideal fuel for smelting iron ore is coal, due to its high energy density and ability to achieve the necessary temperatures for iron production.

How can I optimize the output quality of my blast furnace?

+Optimizing output quality involves precise control over temperature, careful selection and preparation of input materials, and efficient management of fuel consumption. Regular maintenance and calibration of the furnace are also crucial.

What are the environmental considerations of operating a blast furnace?

+Environmental considerations include minimizing fuel consumption to reduce emissions, implementing efficient waste management practices, and ensuring that all operations comply with relevant environmental regulations and standards.

In conclusion, mastering the blast furnace is a multifaceted challenge that requires a deep understanding of its operational principles, a mastery of various recipes, and a strategic approach to optimization and environmental sustainability. By delving into the intricacies of blast furnace operation and implementing best practices, operators can unlock its full potential, achieving high efficiency, quality output, and minimal environmental impact. Whether in industrial production or crafting applications, the blast furnace remains an indispensable tool, and its mastery is a hallmark of expertise in metallurgy and manufacturing.