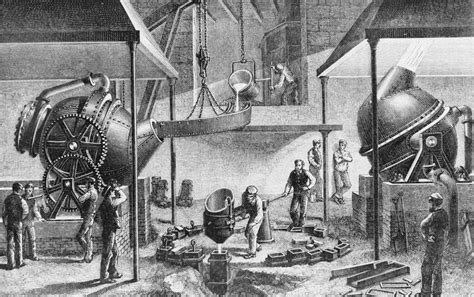

The Bessemer steel process, patented in 1855 by Sir Henry Bessemer, revolutionized the steel industry by introducing a method to mass-produce steel, a crucial material in the construction of railways, ships, and buildings. This innovative process significantly reduced the production time and cost of steel, making it more accessible and affordable for various industries. The Bessemer process involved blowing air through molten pig iron to remove impurities, resulting in a higher-quality steel product. This breakthrough technology played a pivotal role in the rapid industrialization of the 19th century, transforming the steel industry and having a profound impact on the global economy.

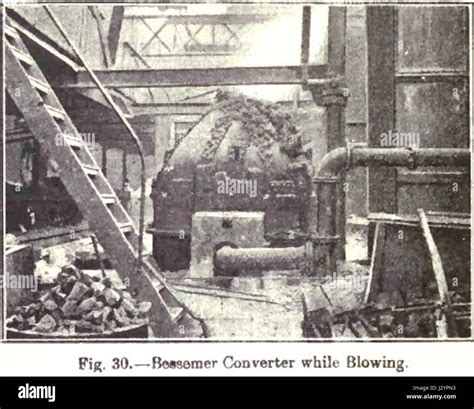

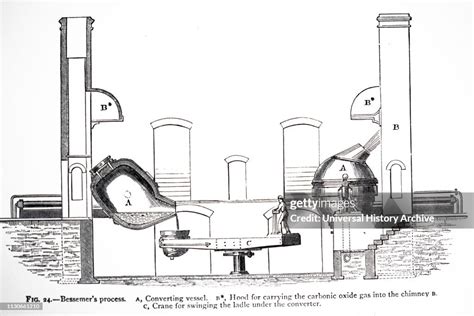

Before the Bessemer process, steel production was a labor-intensive and costly endeavor, limiting its use to small-scale applications. The introduction of the Bessemer converter, a large, cylindrical vessel used to blow air through the molten metal, enabled the mass production of steel. This innovative technology increased steel production from a few hundred tons per year to hundreds of thousands of tons, meeting the growing demand for steel in the construction of railways, bridges, and ships. The Bessemer process also improved the quality of steel, making it stronger and more durable, which was essential for large-scale infrastructure projects.

Key Points

- The Bessemer steel process was patented in 1855 by Sir Henry Bessemer, revolutionizing the steel industry.

- The process involved blowing air through molten pig iron to remove impurities, resulting in higher-quality steel.

- The Bessemer process significantly reduced production time and cost, making steel more accessible and affordable.

- The technology played a crucial role in the rapid industrialization of the 19th century, transforming the steel industry and impacting the global economy.

- The Bessemer process improved the quality of steel, making it stronger and more durable for large-scale infrastructure projects.

The Impact of the Bessemer Process on the Steel Industry

The Bessemer process had a profound impact on the steel industry, transforming it from a small-scale, labor-intensive sector to a large-scale, industrialized industry. The increased production capacity and reduced costs enabled steel to become a widely used material in construction, replacing traditional materials like iron and wood. The Bessemer process also led to the development of new steel products, such as steel rails, steel beams, and steel plates, which were essential for the construction of railways, bridges, and buildings.

The Bessemer process also had a significant impact on the global economy, as it enabled the mass production of steel, a critical material for industrialization. The increased availability of steel led to the growth of various industries, including construction, transportation, and manufacturing. The Bessemer process also created new job opportunities in the steel industry, contributing to the growth of urban centers and the development of new technologies.

Technical Specifications and Process Improvements

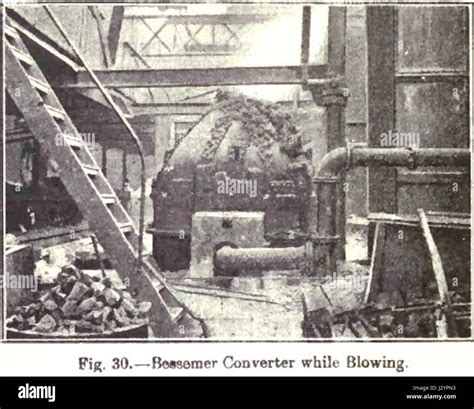

The Bessemer process involved several technical specifications and process improvements that contributed to its success. The Bessemer converter, a large, cylindrical vessel, was used to blow air through the molten metal, removing impurities and producing higher-quality steel. The converter was typically 6-8 meters tall and 2-3 meters in diameter, with a capacity to produce up to 5 tons of steel per batch. The process involved several stages, including charging, blowing, and tapping, which were critical to producing high-quality steel.

| Technical Specification | Value |

|---|---|

| Converter Height | 6-8 meters |

| Converter Diameter | 2-3 meters |

| Production Capacity | Up to 5 tons per batch |

| Blowing Time | 10-20 minutes |

| Tapping Temperature | 1500-1600°C |

Evolutionary Developments and Legacy

The Bessemer process underwent several evolutionary developments and improvements over the years, including the introduction of new technologies and processes. The open-hearth furnace, developed in the late 19th century, replaced the Bessemer converter as the primary method for producing steel. The open-hearth furnace used a regenerative system to improve efficiency and produce higher-quality steel. The basic oxygen furnace, introduced in the mid-20th century, further improved steel production by using oxygen instead of air to remove impurities.

The Bessemer process has a lasting legacy in the steel industry, as it laid the foundation for modern steel production methods. The process enabled the mass production of high-quality steel, which was critical for industrialization and the growth of various industries. The Bessemer process also led to the development of new steel products and technologies, which continue to shape the steel industry today.

Industry Impact and Global Economy

The Bessemer process had a significant impact on the global economy, as it enabled the mass production of steel, a critical material for industrialization. The increased availability of steel led to the growth of various industries, including construction, transportation, and manufacturing. The Bessemer process also created new job opportunities in the steel industry, contributing to the growth of urban centers and the development of new technologies.

The Bessemer process also had a profound impact on the environment, as it enabled the widespread use of steel in construction and other industries. The increased demand for steel led to the growth of the mining industry, which had significant environmental impacts, including deforestation and water pollution. The Bessemer process also contributed to the growth of urban centers, which led to environmental challenges, such as air pollution and waste management.

What was the primary innovation of the Bessemer process?

+The primary innovation of the Bessemer process was the use of a Bessemer converter to blow air through molten pig iron, removing impurities and producing higher-quality steel.

How did the Bessemer process impact the steel industry?

+The Bessemer process transformed the steel industry by enabling the mass production of high-quality steel, reducing production time and cost, and increasing the availability of steel for various industries.

What were the limitations of the Bessemer process?

+The Bessemer process had limitations, including the need for high-quality raw materials and the potential for impurities to affect the final product. The process also required significant capital investment and skilled labor.

In conclusion, the Bessemer steel process was a revolutionary innovation that transformed the steel industry and had a profound impact on the global economy. The process enabled the mass production of high-quality steel, which was critical for industrialization and the growth of various industries. While the Bessemer process had limitations, it laid the foundation for modern steel production methods and continues to shape the steel industry today.