When discussing measurements in millimeters (mm), precision is key. Here are two essential tips to keep in mind:

Understanding Millimeter Measurements

Millimeters are a unit of length in the metric system, where 1 millimeter equals one-thousandth of a meter. This unit of measurement is crucial in various fields, including engineering, architecture, and precision manufacturing. To accurately work with millimeters, it’s vital to understand the context in which they are used.

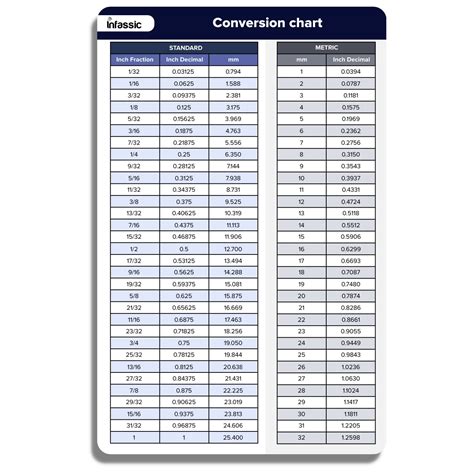

Tip 1: Conversion and Context

The first tip involves converting between different units of measurement and understanding the context in which millimeters are applied. For instance, when converting inches to millimeters, remember that 1 inch equals 25.4 millimeters. This conversion factor is essential for ensuring accuracy in designs and calculations, especially when working with international projects or specifications that require measurements in the metric system.

| Unit of Measurement | Conversion to Millimeters |

|---|---|

| 1 Inch | 25.4 mm |

| 1 Centimeter | 10 mm |

Tip 2: Precision in Measurement Tools

The second tip emphasizes the importance of using the right measurement tools to achieve precision. Digital calipers, for example, can provide measurements in millimeters with high accuracy, often to two decimal places (e.g., 10.05 mm). When selecting measurement tools, consider the required precision for your project. High-precision applications may demand more sophisticated tools, such as micrometers, which can measure even smaller increments.

When working with measurements in millimeters, it's also crucial to follow best practices for reading measurement tools accurately and for recording measurements clearly and consistently. This includes always using the same unit of measurement throughout a project unless otherwise specified and being mindful of the potential for human error in measurement and calculation.

Key Points

- Understand the conversion factors between millimeters and other units of length.

- Choose the appropriate measurement tool based on the required precision.

- Follow best practices for accurate measurement and recording.

- Consider the context and potential applications of millimeter measurements.

- Be aware of the limitations and potential for error in measurement tools and techniques.

In conclusion, working effectively with measurements in millimeters requires a combination of understanding conversion factors, selecting the right measurement tools, and following best practices for precision and accuracy. By keeping these tips in mind, professionals can ensure that their projects are completed to the highest standards, whether in engineering, manufacturing, or any field where precise measurements are critical.

What is the most common use of millimeter measurements?

+Millimeter measurements are commonly used in engineering, architecture, and precision manufacturing due to the need for precise dimensions and specifications.

How do I convert inches to millimeters?

+To convert inches to millimeters, multiply the number of inches by 25.4. For example, 2 inches equals 2 * 25.4 = 50.8 mm.

What tools are best for measuring in millimeters?

+Digital calipers and micrometers are highly recommended for measuring in millimeters due to their high precision and accuracy.